BODYCLAD® COSTUMIZED SURFACES FOR NEW PART PRODUCTION AND REPAIR

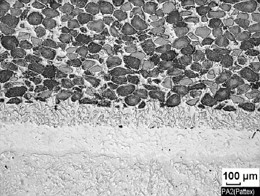

BODYCLAD® is a range of brazed and sintered CerMet coatings developed by EUROMAT GmbH for demanding wear and corrosion protection. These coatings offer special abrasion-minimized surface protection for extreme wear, corrosion and impact stresses, even under high temperature loads.

This program was developed on the basis of many years of experience, material expertise and a profound understanding of surface analysis, material and process selection. Thanks to extensive project and process experience, EUROMAT has established itself as one of the world’s leading suppliers of brazed wear protection solutions based on metal-ceramic (CerMet).

BODYCLAD® is suitable for new part coatings as well as for repairs, e.g. sealing surfaces, guides, molds, tools, etc. The coatings can also be given special functions. E.g. defined roughness for special gripping or friction tasks.

From plastics processing to agricultural, food, transportation, chemical, conveying, separating, granulating, mixing, braking, energy, processing, recycling and safety technology, BODYCLAD® coatings offer unique wear protection.

You can find out which coatings are suitable for your application and what advantages EUROMAT offers you as a partner here

BODYCLAD® brochure